Standard Doors

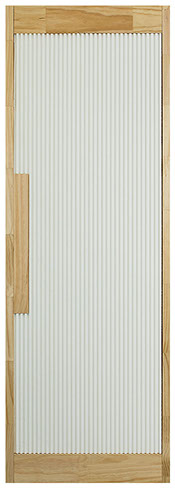

Grooved Doors

Custom/Oversize Doors

The Superior Doors RibCore hollow core interior door range represents industry leading strength and durability with a focus on innovation and attention to detail to produce a truly Superior Door. They are thicker, stronger, offer better impact resistance, greater thermal insulation and are more durable than any other standard hollow core door on the market.

Our standard RibCore achieves about 42% glue adhesion between the core and the door skin while cheaper traditional honey comb paper core used by most other manufacturers has about 4% glued contact between door skin and core. Add together the additional strength obtained using thicker and wider timber and the fact that RibCore has more than 10 times glued adhesion between skin and core and you have one very superior internal door. What this means is simple, a strong door that can easily absorb what life throws at it without popping, bending or bowing. That's what makes a Superior Door, superior.

Standard Cores Comparison

Hover over the plus signs to experience the difference in glue contact area between Superior Doors standard RibCore™ or Solid EPS Core and other traditional Honeycomb Paper Core doors. Greater glue contact equals a stronger more resilient door that won't de-laminate after impact.

Honeycomb Paper Core

RibCore™

EPS Solid Core

View All together

All Core Options

RibCore™

High Contact Hollow Core Polystyrene

EPS Core

High Density EPS Solid Core Polystyrene

MR Core

Solid Core Moisture Resistant Particle Board

Standard Cores - 410-910mm X 1980mm

- Rails : 82mm Finger Jointed Pine for 1980 Height doors

- Rails : 37mm for all other doors heights

- Stiles : 30mm Finger Jointed Pine

- Rails : 27mm Finger Jointed Pine

- Stiles : 30mm Finger Jointed Pine

- Rails : 27mm Finger Jointed Pine

- Stiles : 30mm Finger Jointed Pine

- The ultimate in strength and durability.

- Up to 98% glue contact area

- Will not delaminate after impact

- Enhanced thermal and acoustic qualities

- 398x68mm Finger Jointed Pine

- 398x68mm Finger Jointed Pine

- High Density Solid Core Polystyrene

- Up to 98% Glue Contact area

- Will not delaminate after impact

- Enhanced thermal and acoustic qualities

- Up to 42% Glue Contact area

- Will not delaminate after impact

- Enhanced thermal and acoustic qualities

Steel 1

Steel Insert High Density EPS Solid Core Polystyrene

Steel 2

Steel Insert High Density EPS Solid Core Polystyrene

- Custom designed and precision engineered

- Anti corrosive pre galvanised steel

- 38.1 x 29.9mm with 1.6mm wall thickness for added rigidity

- Base material from New Zealand steel.

- Precision manufactured to 38.1 x 29.9mm, with 1.6mm wall thickness for added rigidity. Pre Galvanised for clean finish.

- Z250 - 275 (Zinc content weight)

- G250 grade material (NZ steel specification)

- 100 percent NZ Made

- ISO9000 Accredited Manufacturer

- Rails : 60mm Finger Jointed Pine

- Stiles : 30mm Finger Jointed Pine

- Rails : 60mm Finger Jointed Pine

- Stiles : 30mm Finger Jointed Pine

- 398x68mm Finger Jointed Pine

- 398x68mm Finger Jointed Pine

- High Density Solid Core Polystyrene

- Up to 98% Glue Contact area

- Will not delaminate after impact

- Enhanced thermal and acoustic qualities

- High Density Solid Core Polystyrene

- Up to 98% Glue Contact area

- Will not delaminate after impact

- Enhanced thermal and acoustic qualities

2200Uni

High Contact Hollow Core Polystyrene

2400Uni

High Contact Hollow Core Polystyrene

2200Uni Steel 1

Steel Insert High Density EPS Solid Core Polystyrene

- Rails : 132mm Finger Jointed Pine

- Stiles : 40mm Finger Jointed Pine

- Rails : 132mm Finger Jointed Pine

- Stiles : 40mm Finger Jointed Pine

- Rails : 168mm Finger Jointed Pine

- Stiles : 40mm Finger Jointed Pine

- 640x68mm Finger Jointed Pine

- 640x68mm Finger Jointed Pine

- 640x68mm Finger Jointed Pine

- Up to 42% Glue Contact area

- Will not delaminate after impact

- Enhanced thermal and acoustic qualities

- Up to 42% Glue Contact area

- Will not delaminate after impact

- Enhanced thermal and acoustic qualities

- High Density Solid Core Polystyrene

- Up to 98% Glue Contact area

- Will not delaminate after impact

- Enhanced thermal and acoustic qualities

2200Uni Steel 2

Steel Insert High Density EPS Solid Core Polystyrene

2400Uni Steel 1

Steel Insert High Density EPS Solid Core Polystyrene

2400Uni Steel 2

Steel Insert High Density EPS Solid Core Polystyrene

- Rails : 168mm Finger Jointed Pine

- Stiles : 40mm Finger Jointed Pine

- Rails : 168mm Finger Jointed Pine

- Stiles : 40mm Finger Jointed Pine

- Rails : 168mm Finger Jointed Pine

- Stiles : 40mm Finger Jointed Pine

- 640x68mm Finger Jointed Pine

- 640x68mm Finger Jointed Pine

- 640x68mm Finger Jointed Pine

- High Density Solid Core Polystyrene

- Up to 98% Glue Contact area

- Will not delaminate after impact

- Enhanced thermal and acoustic qualities

- High Density Solid Core Polystyrene

- Up to 98% Glue Contact area

- Will not delaminate after impact

- Enhanced thermal and acoustic qualities

- High Density Solid Core Polystyrene

- Up to 98% Glue Contact area

- Will not delaminate after impact

- Enhanced thermal and acoustic qualities

Skin Options

At Superior Doors we offer a range of skin thicknesses to suit most situations and needs. Thicker door skins increase strength and durability, allow for deeper more substantial grooving and reduce component show through for a flatter higher quality finish.

UV Pre Primed Skins

The use of UV primer represent additional benefits to the home owner and the environment they live in. UV primer is both moisture and solvent resistant, harder and more scratch resistant and offers greater fire resistance than normal door priming solutions. In addition to its general resistance it is also formulated to offer optimal adhesion for all main stream finishing coats.

UV primer is also solvent, formaldehyde and V.O.C ( Volatile Organic Compounds ) free. The coating process is energy efficient unlike the heat drying processes used to evaporate water based solutions. UV primer can also be disposed of without additional processing via landfill, incineration or recycled into pulp

The Superior Difference

Downloads

Contact

Copyright 2015 Superior Doors Ltd (SDL) all material, images, artwork and copy on the SDL website is the copyright of SDL.